When I was painting the hull sides/deck it took longer to tape and strip all the edges than it did to actually paint. Below is looking forward when I was painting the deck, the majority of the deck got non slip after this.

And looking aft:

Once the final coat was dry, it was time to do the same with kiwigrip non slip. First job was to tape up the edges (again). Bought four litres, watched a few Youtube videos from the company and others applying it and away I went. Below is the non slip area taped out, stb side looking forward.

And the front deck underway:

And working my way aft down the port side. Not much time for photos, too busy trying not to stuff it up.

Peeled off the tape as I went, it is very viscous and didn't run. Once it was dry it looked like this, it is hard to make out in normal light but feels good underfoot.

And a close up of the stb deck looking aft.

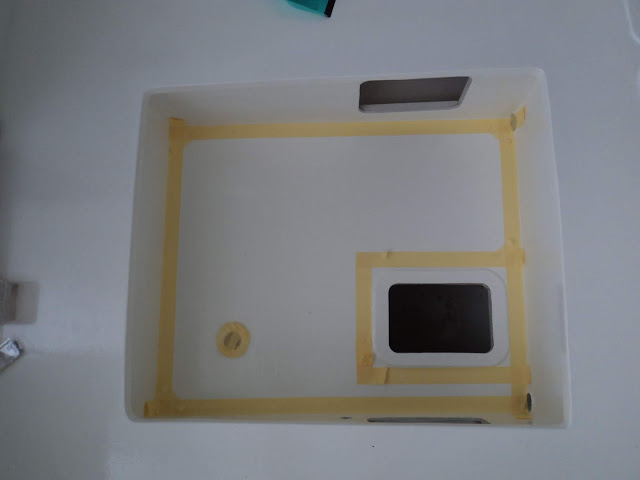

I later went back and did the cockpit and anchor locker. Below is the cockpit floor taped up, left side is forward. Not sure if or how much of the cabin top I will do. I think I will wait a bit and see, still drying so I haven't taken photos of it. Anchor locker is almost invisible because I left the weave of the fibreglass visible under the paint.

Once the deck was done I started to think of putting things in place for the last time. Only got as far as the deck locker lids and the covers for the cabin vents, but it felt like a step towards dragging this thing out of the shed.

And a close up of one of the locker lids. Stainless steel screws and hinges, rubber tie down strap.

Other than that I have been slowly finishing sanding the keel prior to epoxy sealer and then undercoat. In the meantime I have been having a play at making some handrails for the rear quarter deck forward to the end of the cockpit combings.

Uprights and top rail are 35mm Tasmania oak hardwood, and the lower cross brace is 25mm Merbau/Kwila. Uprights are notched into the top piece using a 35mm spade bit and then epoxy glued and screwed in from the top with 14guage x 1 1/2 inch stainless steel screw each side. Smaller cross piece just glued.

Close up of the smaller cross brace, before sanding.

The feet are 20mm x 70mm hardwood, again cut out holes for the uprights to sit in for epoxy glue.

Below is one with the epoxy drying. I put temporary screws in through the bottom of the feet to hold it together which were later taken out.

Below are the two rear ones sitting in place on the quarter deck after some adjustments to the base to get them to sit as close as possible to the curved surface. The plan is to continue another section forward each side to meet the rear of the cockpit combing.

The upright for the front section will be bolted through the combing edge on the outside. I have drilled the holes each side oversize and filled them with epoxy, I will then drill out 8mm holes for the threaded rod. I am glad I left a section of the combing hanging over, hopefully will work out!

And a photo of the uprights before I epoxied in the threaded 8mm rod. Drilled up into the wood 80mm and left 30mm out to pass through the coaming (20mm wood) and leave enough for a washer and galvanised nut.

I have ordered some butyl tape and when it arrives will fit the portholes and locker access lids in the cockpit. That should look like progress, and I will continue with the handrails and prep for keel painting.