So I followed the building guide's other suggestion, which was to substitute the middle section with a marine alloy tube. Mine is 6.5m long, 100mm in diameter and a couple of mm thick. It weighs about 16kg from memory and easy to carry. The top and bottom sections have solid wood pieces that are a tight fit to slide in, through bolted once the tube is in place. The whole completed mast is 9.8m long, and too long to fit neatly into the shed.

Below is the bottom wooden section of the mast. The silver bit half way up is the pivot pin which is stainless steel and fits in the tabernacle. The base piece is hollow for a small section between the base and the solid bit for the pin, and between the pin and the top. The bit that sticks up is solid wood and continues below the platform the same distance it goes above it for strength.

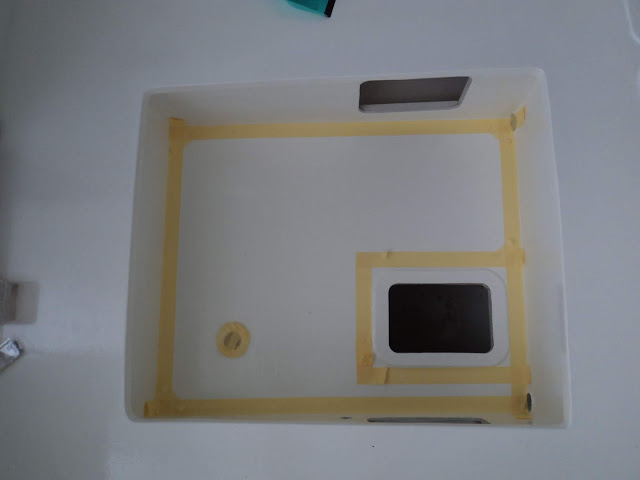

This is a close up of the platform for the boom jaws to pivot on, the hardwood supports it rests on and the space inside where the alloy tube slides down. The hole is one of two drilled through for 6mm stainless steel bolts. The bolts overlap in an X 10-15mm apart for strength.

This is the top section, the edge you can see on the left is the forward one, on top is a platform with the tri-colour/anchor light and behind it a wind vane.

After some swearing and several attempts I managed to get five strand 12 volt trailer wire through. This allows extra wires for down the track if I need them. Below you can see the wire before I attached the top to the alloy tube.

And this is with the alloy tube attached. Because of the wires I couldn't alternate the direction of the bolts. I'll talk to the rigger down the track and strap it if necessary to re-enforce it.

The tube attached to the bottom section:

And a close up of the bolts.

We are now almost up to date. I have cut a slot in the bowsprit and fitted it over the stem fitting with the aft end bolted and supported into the fitting in the anchor well. Photos to follow.

2019 will be launch year, I am running out of jobs that I will do myself.............

Scary.